Your company should not stop, for a minute

How we save money

By Generating Availability

Find out how we are empowering operations at every stage

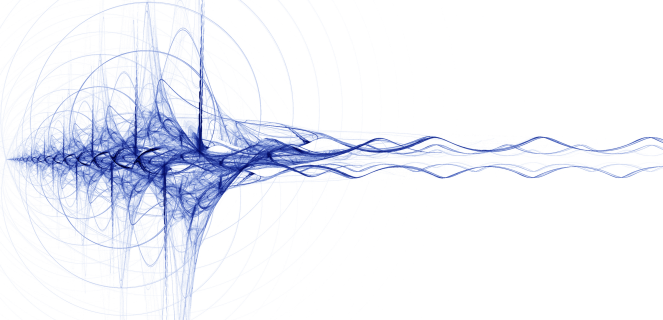

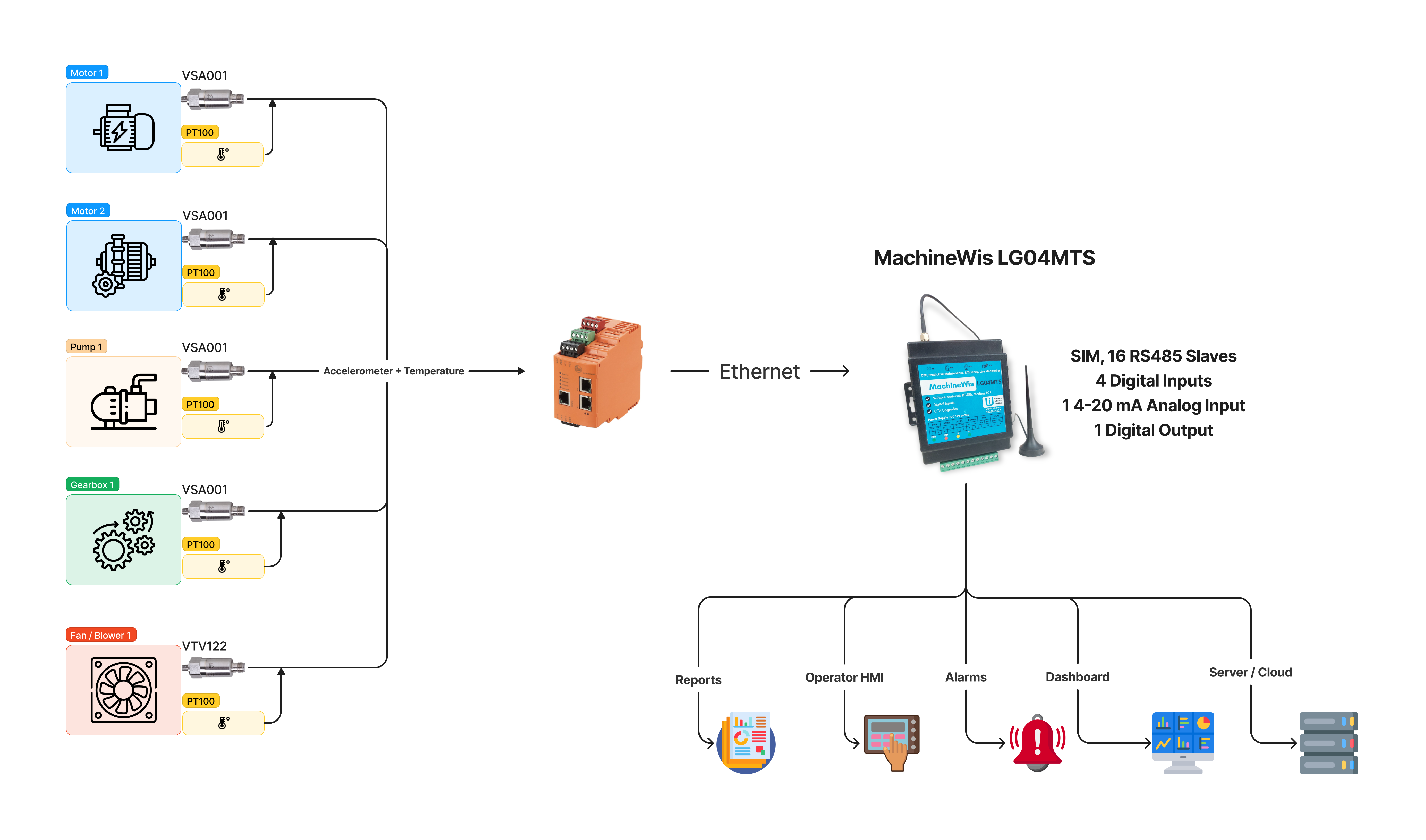

Vibration Monitoring

Maximizing Equipment Efficiency and Longevity

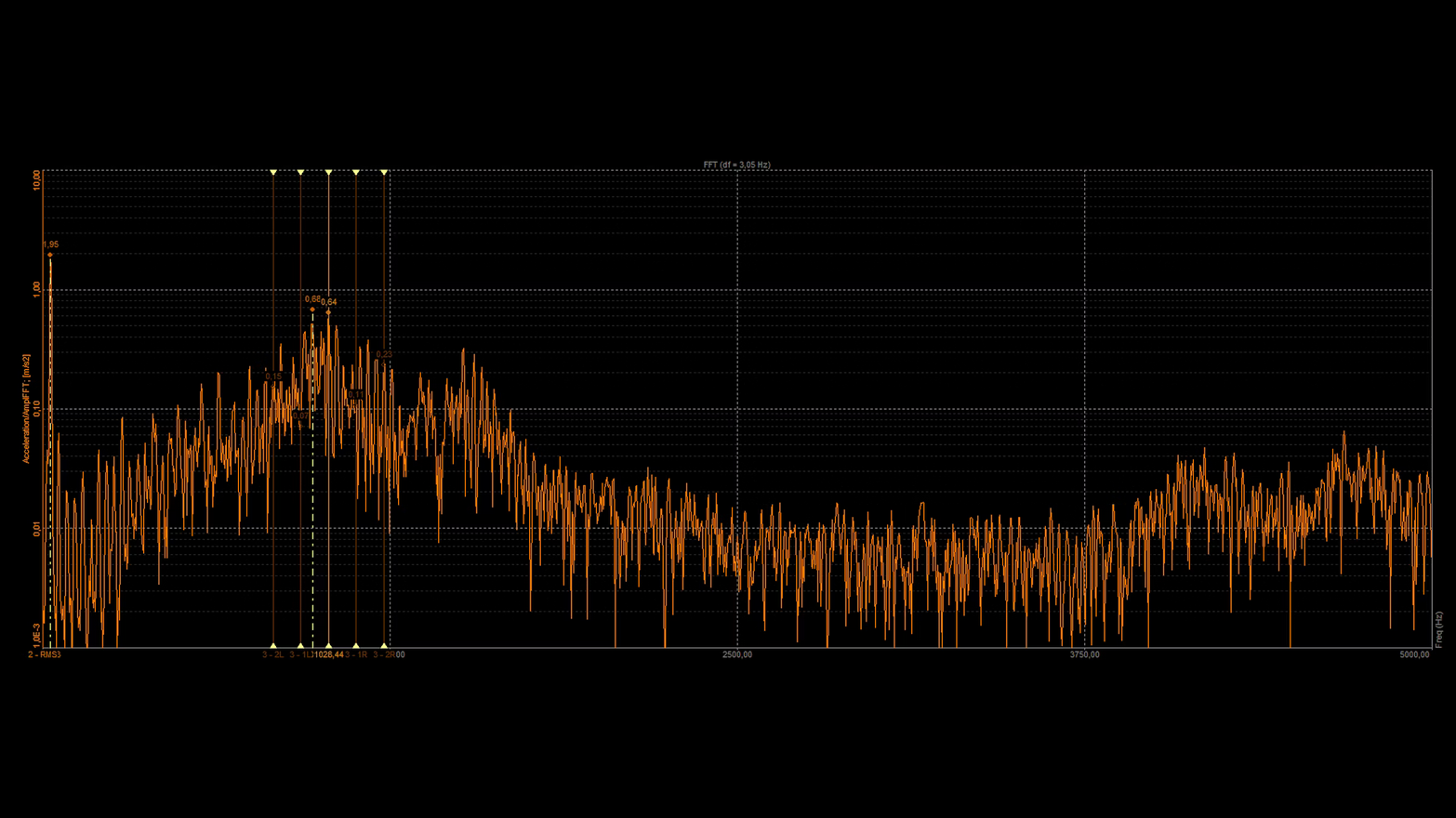

FFT (Fast Fourier Transform) Analysis

Precision Frequency Analysis for Optimal Maintenance with Over 100,000 Samples Per Second

Condition Monitoring with Pressure and Oil

Real-time Analysis for Enhanced Equipment Health

Find a sensor that’s right for you

Whether you are looking for Continuous Vibration Monitoring or In-Depth Analytics;

We have you covered!

Predictive Maintenance

Empowering Operational Excellence through Predictive Maintenance Solutions with MachineWise

With MachineWise’s advanced predictive maintenance capabilities, we ensure the seamless performance of vital industrial components such as pumps, motors, fans, gearboxes, turbines, and more. By harnessing cutting-edge monitoring technologies and data-driven insights, we enable proactive maintenance strategies that prevent unexpected downtime and optimize the efficiency and longevity of your critical machinery. Trust MachineWise to safeguard the continuous operation of your industrial assets, minimizing disruptions and maximizing productivity for sustained business success.

Get an estimate of your project’s time and costs.

See current openings

Interested in starting a project?

Thank you for your interest in Elevated Maintenance with MachineWise.

We are just a click away!