Condition Based Monitoring

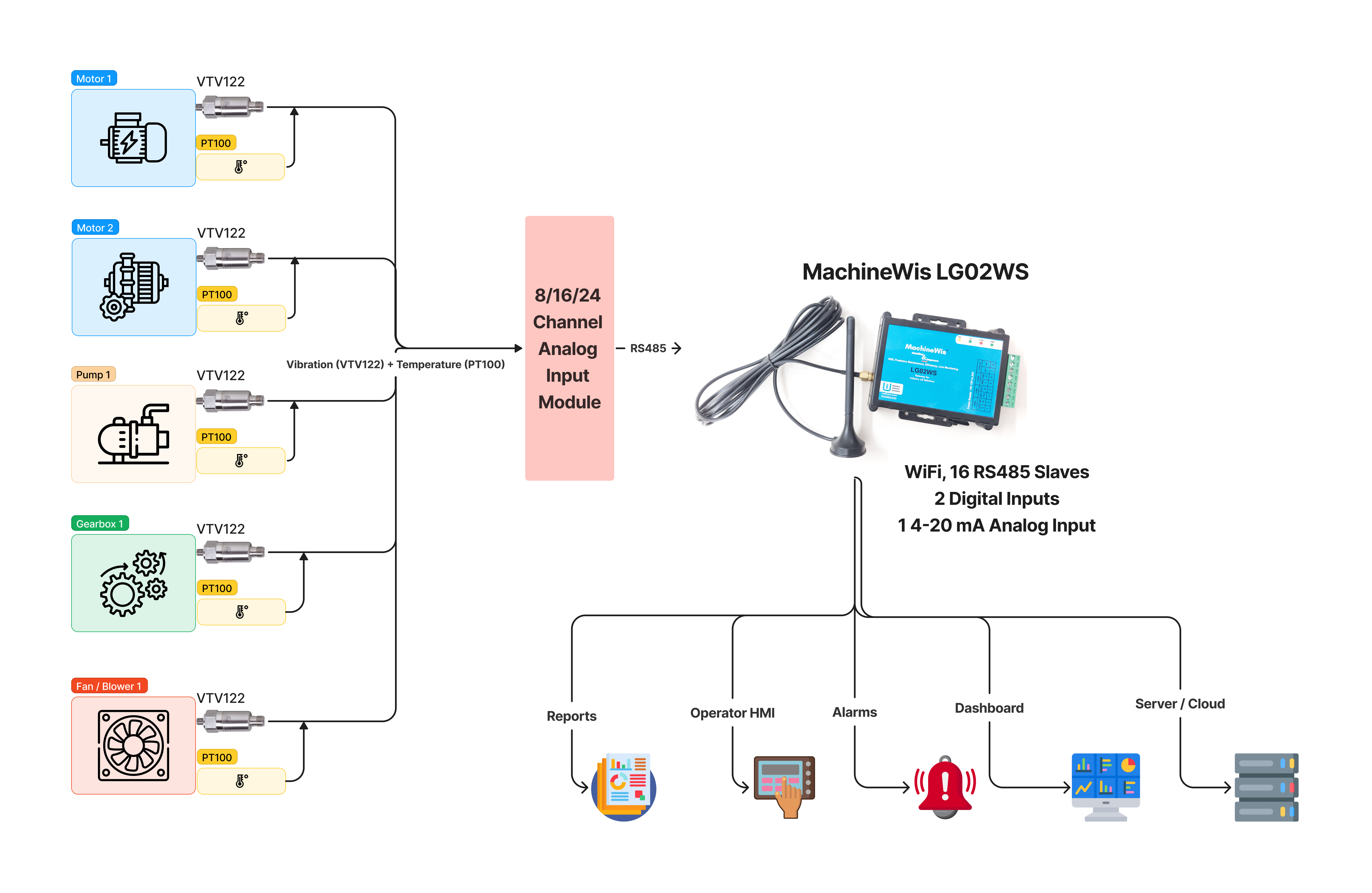

MachineWise’s Condition-Based Monitoring solution utilizes cutting-edge sensor technology and advanced data analytics to provide real-time insights into equipment health. By continuously monitoring various parameters such as vibration, temperature, and oil quality, our solution enables proactive maintenance planning, ensuring early detection of potential issues and preventing costly downtime. With MachineWise, you can optimize your industrial operations by minimizing the risk of unexpected failures and maximizing overall productivity.

Condition Based Monitoring

MachineWise - Condition Based Monitoring

We monitor Vibration, Pressure, Oil Level, Oil Quality, Temperature, Noise and other parameters for perfect machine health, all the time.

Get an estimate of your project’s time and costs.

See current openings