Optimizing Performance with Advanced Test Bed Monitoring Systems

Discover our comprehensive test bed monitoring solutions that enable businesses to conduct efficient and accurate performance analysis across various industrial sectors. With advanced data tracking and in-depth analytical tools, our systems are designed to streamline testing procedures, ensure product reliability, and optimize overall operational efficiency.

Quality Assurance with MachineWise

est bed monitoring is indispensable for all OEMs, ensuring product quality, reliability, and adherence to industry standards, while the integration of MachineWise Gateway and Software Platform is crucial to streamline data acquisition, optimize testing processes, and ensure precise performance analysis for unmatched product excellence and customer satisfaction.

Implementation of Gateway for Data Acquisition

Seamlessly integrate our advanced gateway system to acquire essential data from various testing equipment, ensuring comprehensive and real-time data collection for thorough performance analysis.

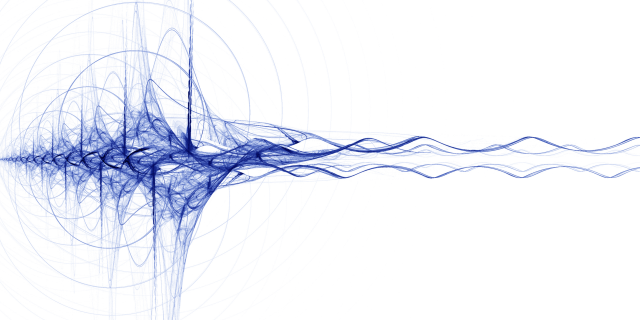

Connected Sensors Generating Data Every Second or Less for Testing Duration

Utilize our high-performance sensors to capture critical data at sub-second intervals throughout the testing duration, providing precise and detailed insights into product performance and reliability.

Detailed Generated Report for Customer Satisfaction

Receive a comprehensive and meticulously generated report that outlines all testing parameters, results, and insights, ensuring customer satisfaction and facilitating informed decision-making for future product enhancements and optimizations.

Where and Why

Test Bed Monitoring should be done