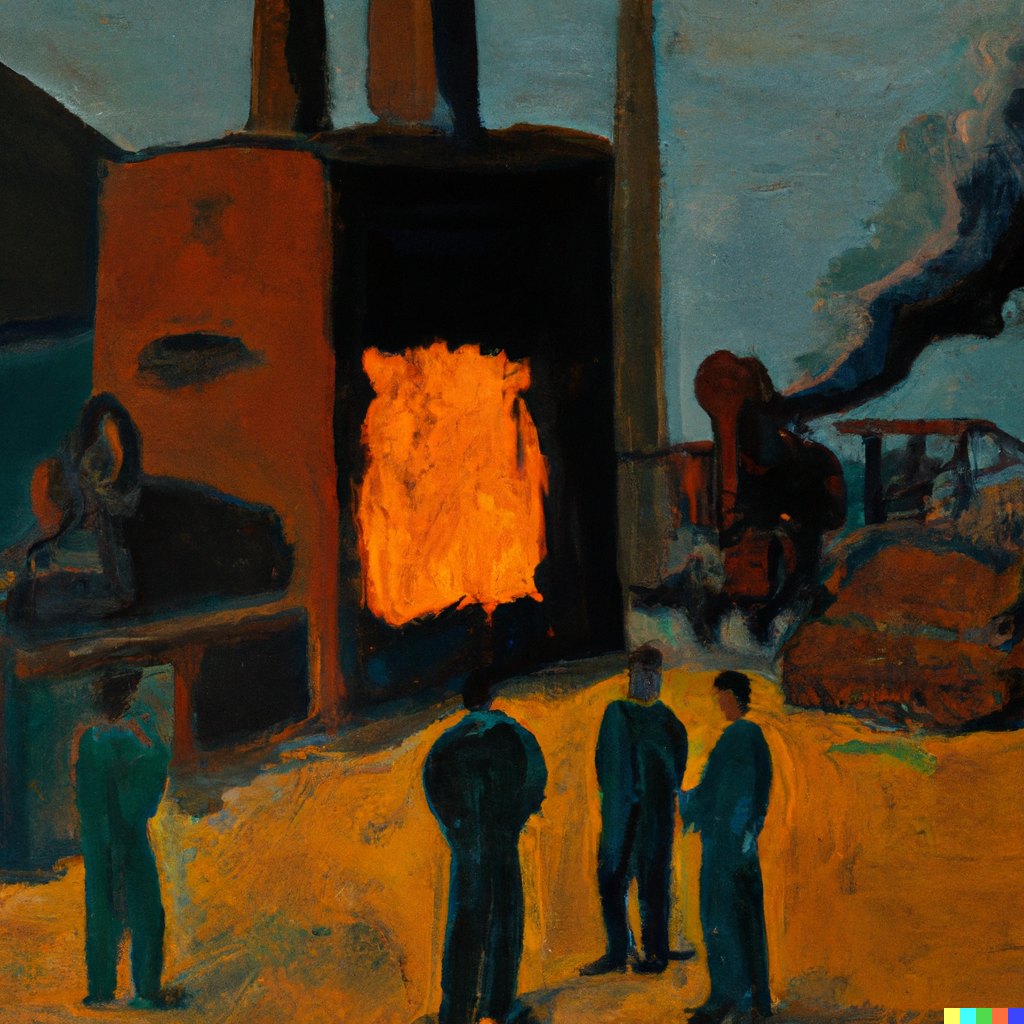

Foundries play a critical role in manufacturing industries, producing various metal castings that are used in a wide range of applications. To ensure optimal performance and efficiency, foundries must continuously monitor key parameters such as energy consumption, temperature, and cycle times. MachineWise offers comprehensive monitoring solutions tailored specifically for foundries, providing real-time insights and enabling predictive maintenance strategies.

Energy Monitoring

Energy consumption is a significant cost factor for foundries. By monitoring energy usage, foundries can identify inefficiencies and implement measures to reduce energy waste. MachineWise’s energy monitoring system provides detailed analytics and reports, allowing foundries to optimize their energy consumption and reduce operational costs.

Temperature Monitoring

Temperature control is crucial in foundry operations to ensure the quality and integrity of castings. MachineWise’s temperature monitoring system offers real-time monitoring and alerts, enabling foundries to maintain optimal temperature levels throughout the production process. This helps prevent defects, improve casting quality, and minimize scrap rates.

Cycle Time Monitoring

Cycle time monitoring is essential for foundries to identify bottlenecks, optimize production processes, and ensure timely delivery of orders. MachineWise’s cycle time monitoring system provides detailed insights into each stage of the production cycle, allowing foundries to identify areas for improvement and enhance overall efficiency.

Additionally, MachineWise offers other monitoring solutions such as harmonics monitoring, predictive maintenance, hold cycle monitoring, and melt cycle monitoring. These solutions further enhance foundries’ operational efficiency and help prevent costly downtime.

Take control of your foundry operations today. Contact MachineWise to schedule a meeting and discover how our monitoring solutions can benefit your business.

Call us today at 9423865420 to schedule a meeting.